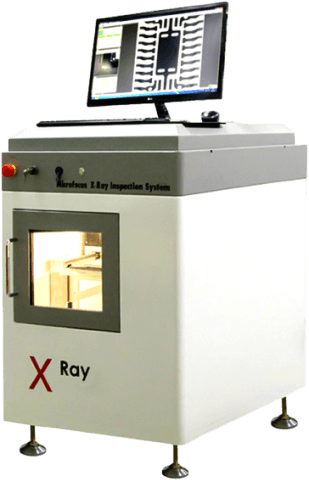

EXTERNAL VISUAL INSPECTION

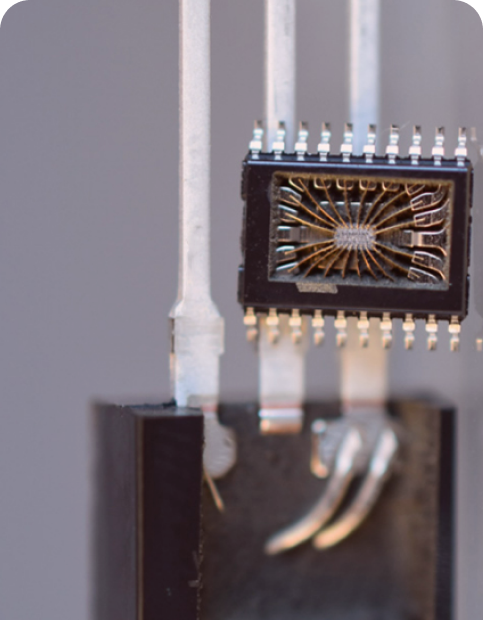

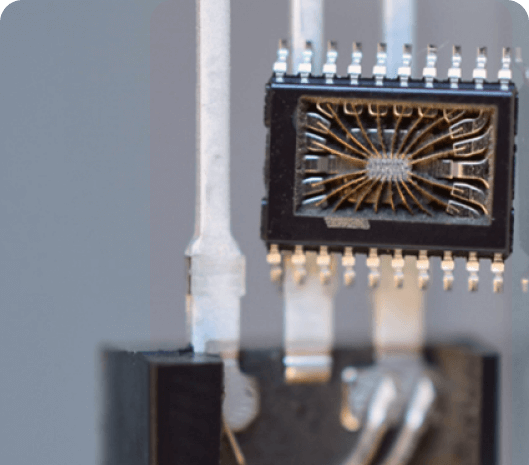

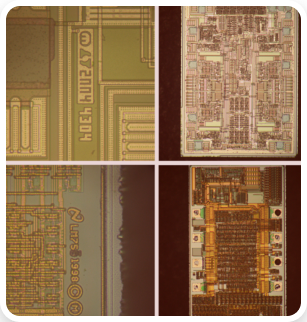

This inspection verifies the characteristics of electronic parts to evaluate quality and originality. This includes inceptions such as the condition of the components, part markings, evidence of a secondary coating, lead conditions, dimensions and surface quality. Visual inspection is non-destructive and performed per SAE AS6081 and MIL-STD-883 Method 2009.9 and on a sample of parts from a given lot base on the sample according to the ANSI ASQE Z1.4 Table II−A. Common things generally looked for during a visual inspection test of an Integrated Circuit device include:

- Packing material / External visual inspection (MSL; ESD)

- Chemical Removal Test

- External Microscopic Inspection

- Components Cracks,Scratches & Contaminants verification

- Top Surface Consistency

- Surface Finish

- Pins Alignment

- Pin One Indicator

- Pins oxidation detection

- Dimensions

- Font and Logo Consistency

- Traceability digital records kept of all goods inspected

- Physical Removal Test